About Us

What We Are

PDC is an innovative supplier of brass, aluminium and zinc castings to the South African and international markets. We are a specialist die caster, who has been in business since 1952.

We have built our company customer by customer. Our approach is to start from our customer’s need exploring various design options until we identify the best process solution. This approach is valued by our customers who are then confident that the process we design for them will best meet their requirements.

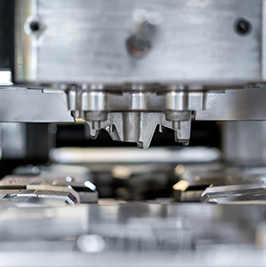

Our team of specialist engineers translates the concept into the working steel dies that are used to repeatedly make quality components. Our sophisticated tool room is an integral part of the process and critical to the successful manufacture of high quality products. All tools and dies are made and serviced in our own toolroom.

We have a fully integrated process line from sourcing raw materials, to tool making and manufacturing in house which enables us to deliver a quality product, on time.

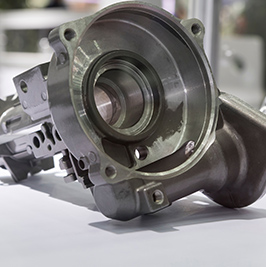

We have extensive experience in the manufacture of a range of components with weights from just a few grams to 800 g with current production runs from 1 000 to millions of components per annum. The manufacturing process that a component follows varies according to its complexity and sub-assemblies are made according to the customer’s brief. We are always open to increasing our capabilities to meet a customer’s specific needs.

We manufacture more than 100 different components for a number of diverse industries, the primary ones being; the building hardware industry, the fire protection industry, the power reticulation industry, the automotive components industry, the plumbing components industry and the electrical illumination industry. More than fifty percent of our production is exported.

PDC has been a certified ISO9001 company since 1997 and is audited regularly to ensure conformity and continuous improvement.

We at PDC strive to always improve and spend time developing new ideas that ensure our processes and systems stay at the cutting edge of technology. We are committed to improving our productivity and equipment to ensure our customers get quality products all the time.

We are a full service supplier working with our customers to provide a die casting solution that includes:

- Component design

- Tooling design

- Tool and die manufacture

- Material alloying and analysis

- High pressure die casting

- Fettling and CNC machining

- Testing and assembly

- Metrology

- Packaging and logistics

Vision

PDC is a dynamic and thriving organisation, providing sustainable growth through the delivery of innovative solutions to our customers. We embrace technology and advancement and are an employer of choice.

Mission

PDC is an innovative manufacturing specialist of cast non-ferrous metals and other fabricated products to industry.

Values & Norms

Commitment to business vision, act with integrity, mutual respect, first time right, do what we say and collaborative support.

Our People

PDC is extremely proud of the relationships it has built with employees and believes this to be a significant contributing factor to the long term sustainability of the company. Close to 60% of staff have worked for the company for more than five years.

Our success depends on our people and our formalised training strategy, which includes an extensive apprenticeship, study aid policies and learnership programmes. This ensures an improved and relevant skill set. PDC currently employs apprentices who are studying to become qualified toolmakers, boilermakers and electricians.

We operate an intensive and interactive health and safety programme, which ensures safe working conditions for all our employees. All safety equipment is supplied to our staff. They have the benefits of optical glasses and personal protective equipment such as hearing protection and safety glasses.

We have a clinic on site that is manned by professionals which addresses all aspects of occupational health. We have an active HIV/Aids programme and a full time lifeline counsellor to support our staff. We also hold interactive AIDS workshops facilitated by peer educators who come from within the company and have been accepted by the staff as knowledgeable and trusted sources of information on HIV/AIDS.

Innovation

Our company is known for being first to try out new ideas, innovations and processes. As a result of the open environment and management style at PDC, a number of ideas and innovations are actively pursued, recorded and implemented. The innovation programme is critical to increasing productivity and managing costs.

The Environment

PDC is aware of the impact business has on the environment. Our commitment to this is shown by:

- The use of recycled scrap brass material (to which copper and zinc are added) as well as recycled aluminium as our primary sources of raw material.

- An Environmental Management Programme which closely monitors our waste products including water, air and the by-products of our processes.

- Active energy reduction programmes.

Export

PDC has been involved in the exporting of product for over two decades. We have grown our exports and currently export approximately 50% of our product around the world.

We understand the logistics of exporting which enables us to supply a seamless flow of production to our customers.